Description

Characteristics and Features:

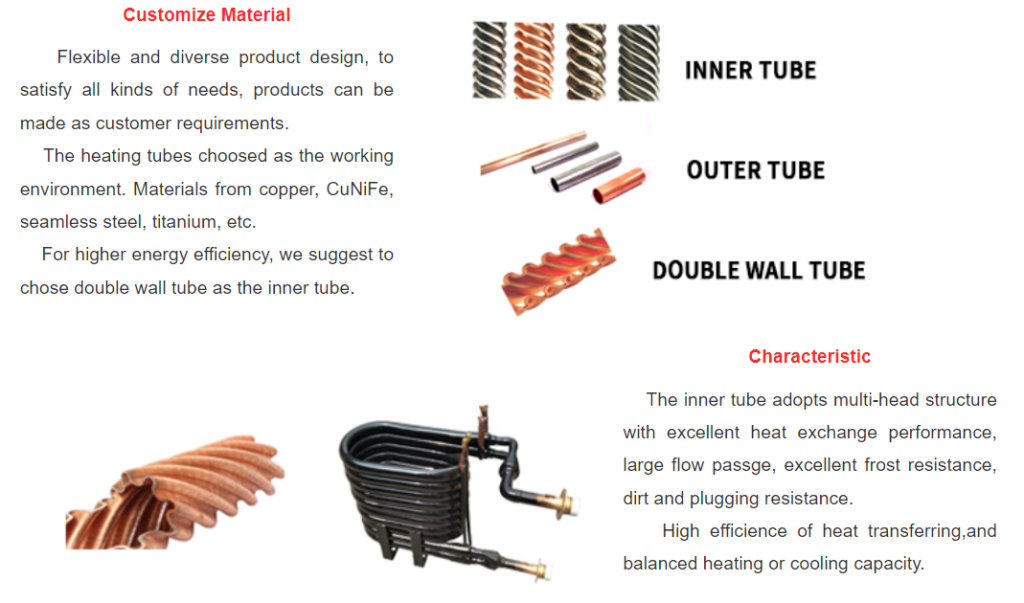

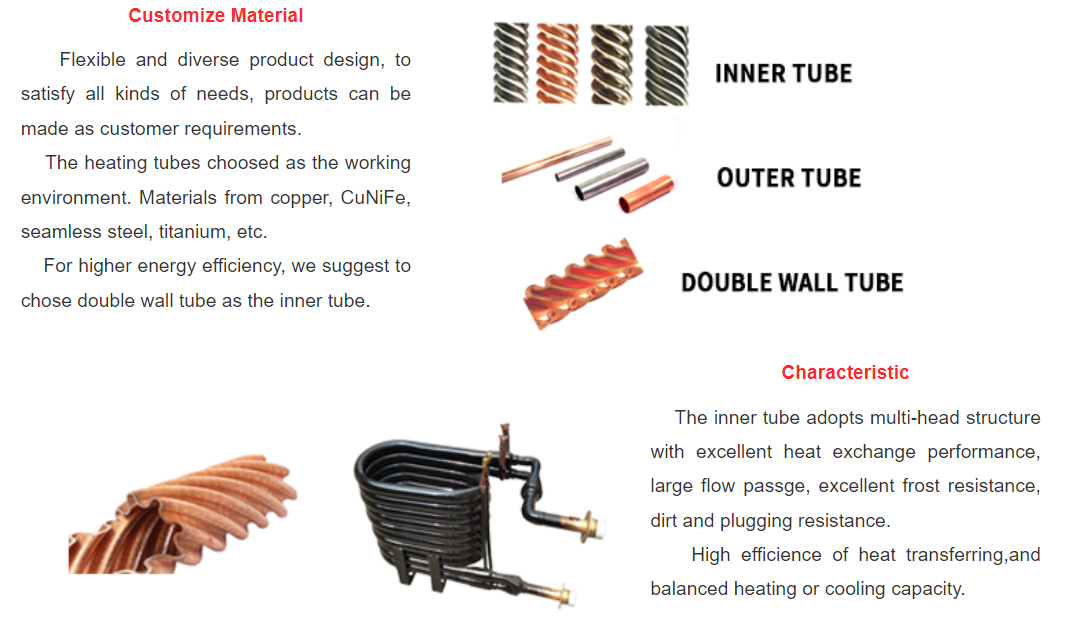

Coaxial Design: The coaxial heat exchanger consists of an inner tube or coil through which one fluid flows, surrounded by an outer tube or coil through which another fluid circulates. This design maximizes the surface area available for heat transfer, enhancing efficiency.

Efficient Heat Transfer: The counterflow or parallel flow pattern of the fluids within the coaxial heat exchanger promotes efficient heat exchange. The close proximity of the fluids allows for optimal thermal transfer, leading to improved performance and energy efficiency.

Compact Size: The coaxial design offers a compact and space-saving solution, making it suitable for applications with limited space constraints. It provides a high heat transfer rate within a relatively small footprint.

Versatility: The coaxial heat exchanger can handle a wide range of fluids, including liquids, gases, or a combination of both. It is versatile and adaptable to various applications in HVAC systems, refrigeration, heat pumps, and other industrial processes.

Reduced Fouling and Maintenance: The coaxial design minimizes the chances of fouling or clogging, reducing maintenance requirements and ensuring a long operational lifespan. The smooth inner surface of the coaxial tubes promotes self-cleaning.

Advantages over Other Types of Heat Exchangers:

Enhanced Efficiency: The coaxial heat exchanger provides high heat transfer efficiency due to its close proximity between the fluids, resulting in improved overall system performance.

Compact Design: The coaxial heat exchanger’s space-saving design allows for installation in tight spaces or applications where a smaller footprint is desired.

Reduced Installation Costs: The compact size and simplified installation requirements of the coaxial heat exchanger can lead to cost savings during the installation process.

Lower Pressure Drops: The coaxial design typically results in lower pressure drops, minimizing energy consumption and reducing pumping requirements.

Specifications

| Product Name | Coaxial Heat Exchanger |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurants, Home Use, Retail, Food Shop, Printing Shops, Construction works, Energy & Mining, Food & Beverage Shops, Advertising Company… |

| Liquid Flow Rate | Depends |

| Voltage | Depends |

| Dimensions | Depends |

| Certification | CCC, RoHS |

| Working Temperature Range | -50-150℃ |

| Place of Origin: | China |

| Maximum Working Pressure: | 3.5Mpa |

| Supply | 120V-60Hz |

| Exchanger | titanium |

Series Comparison

| Model | HP | Kw | Size(mm) | Refrigeration inlet&outlet(mm) | Water inlet&outlet (mm) | ||

| Length (mm) | Width (mm) | Height (mm) | |||||

| SHCHE-101CHTI-1R | 1 | 3.5 | Φ195 | 180 | 12.7 | 32 | |

| SHCHE-102CHTI-1R | 1.5 | 5.25 | Φ220 | 225 | 12.7 | 32 | |

| SHCHE-103CHTI-1R | 2 | 7 | Φ245 | 250 | 12.7 | 32 | |

| SHCHE-104CHTI-1R | 3 | 10.5 | Φ265 | 280 | 12.7 | 32 | |

| SHCHE-105CHTI-1R | 4 | 14 | 451 | 267 | 369 | 12.7/19 | 32 |

| SHCHE-106CHTI-1R | 5 | 17.5 | 542 | 280 | 280 | 12.7/19 | 32 |

| SHCHE-107CHTI-1R | 6 | 21 | 547 | 280 | 280 | 12.7/19 | 32 |

| SHCHE-108CHTI-1R | 10 | 35 | 552 | 280 | 480 | 12.7/19 | 32 |